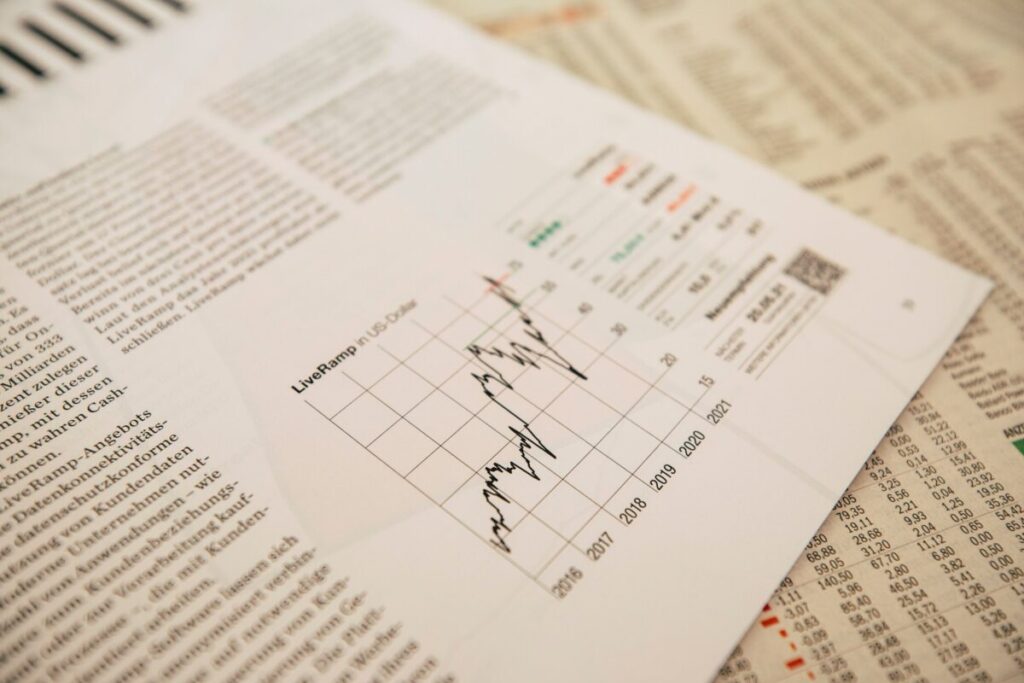

Though predictive maintenance methods and technologies are by no means a new sector, market studies indicate that it is only in it’s nascency in terms of development. Having doubled between 2016 to 2022, new technologies are now driving growth at an estimated 30% per annum.

The new technologies, such as machine learning, wireless sensors and the cloud, are changing the field from unplanned, reactive condition monitoring to planned asset management and reliability services. At the same time cost per asset has come down to the level where any asset regardless of cost is worth connecting and deployment is fast to cover large fleets without excuses.

Recent studies also highlight another driver, that is fuelling the development. Availability of qualified workforce along with labour costs is forcing organizations to change their processes and work methods. When in the past a team was sent to check manually on an asset on location, now technology delivers the status of an asset, along with AI-based suggestions of needed spare parts and estimated time-to failure predictions. Up to 20% of the respondents in an EMAM survey said recruiting was next to impossible. The investments to tackle this driver will focus on ICT/digitalization tools with reliability and cost optimization as goals.

The EMAM 23 survey by EFNMS identified various several factors that are critical to the ICT- and digitalization deployment. The two factors that got the most mentions were management commitment and a clear maintenance strategy and development plan. According to another study done by IoT-Analytics, predictive maintenance has grown from a marginal player to a clear category winner that also has a very short payback time.

Overall, predictive maintenance is at an inflection point. New technologies are helping service organizations not only tackle resource bottlenecks but also to increase productivity at an accelerating pace. The technology is mature, scalable, and readily available. Together with real time analytics and AI-based predictions it can increase the productivity of both the service organization as well as the core process that it serves, boosting reliability and asset life.

For more about reliability and asset performance solutions, please visit condence.io.

References:

Promaint magazine 4/23, in Finnish.

EMAM 23 kysely, EFNMS

0 Comments